Strong Point

- This is suitable for brazing of pure titanium and titanium alloy.

- It is possible to braze pure titanium at lower temperature than βtransus temperature.

- This brazing alloys has the same corrosion resistance as titanium because it is powder alloy which mainly consists of titanium and zirconium.

Table of Titanium based brazing alloys

| TYPE | AWS standard(AWS) | Chemical Compositions (Wt%) | Melting Range(℃) | Specific Gravity | |||

|---|---|---|---|---|---|---|---|

| Ti(%) | Zr(%) | Cu(%) | Ni(%) | ||||

| TB-1510 | BTi-3 | 37.5 | 37.5 | 15 | 10 | 842 | 6.2-6.5 |

| TB-2020 | BTi-5 | 40 | 20 | 20 | 20 | 820-880 | |

| TB-2500 | – | 37.5 | 37.5 | 25 | – | 825 | |

| TB-5000 | – | 25 | 25 | 50 | – | 810-860 | |

Test of corrosion resistance(720hours dipping)

This shows the same corrosion resistance as based metals.

- We have 2types of Titanium based brazing alloys Paste and powder

- It is used in vacuum or in the non-active gas atmosphere

- The joint strength changes according to the shape of joint or the condition of brazing.

Example of application

- Medical part

- Parts for aircraft

- Parts for semiconductor device

- Parts for automobile for competition

- Parts for cutting tool

- Mug as consumer product

- etc.

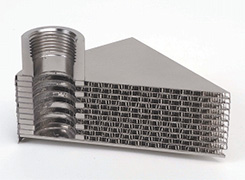

Parts for automobile for competition

Medical parts

Parts of heat exchanger (Cross section)